With the global rise of electric vehicles, managing millions of end-of-life batteries has become a crucial challenge. While spent batteries still contain valuable lithium, conventional recycling methods for lithium-iron-phosphate (LFP) packs are often energy-intensive and generate substantial waste. A research team at the University of Wisconsin–Madison, led by chemistry professor Kyoung-Shin Choi, has developed a new electrochemical process that could make lithium recovery from LFP batteries more economically viable.

The two-step method begins by leaching lithium ions from shredded LFP material into an electrolyte solution. A specialized lithium-ion storage electrode then selectively captures the ions. In the second step, those ions are released into a separate recovery solution, yielding high-purity lithium chemicals suitable for new battery production.

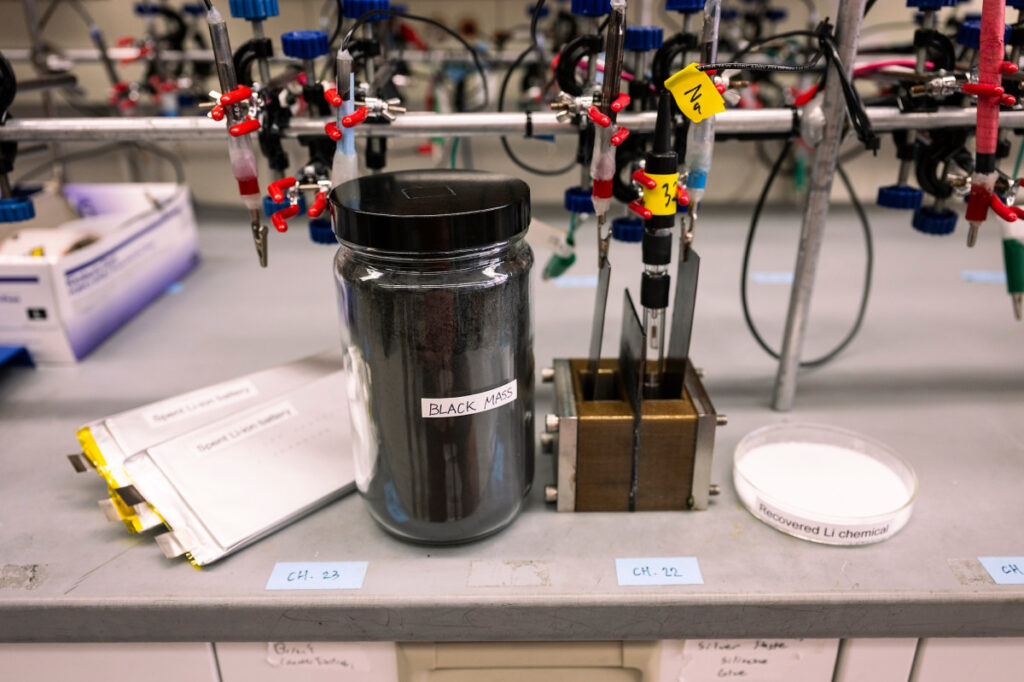

Choi’s group demonstrated the technique using both commercial LFP cells and industrial “black mass” derived from spent batteries. The results, recently published in ACS Energy Letters, show lithium recovery rates competitive with existing methods but at lower operational costs. The team has filed a patent through the Wisconsin Alumni Research Foundation and is engaging with battery makers and automakers interested in strengthening supply-chain resilience.

The timing is significant: starting in 2031, new electric vehicles sold in the European Union must contain a minimum percentage of recycled lithium. Meeting this regulatory requirement will depend on cost-effective recycling solutions. Choi’s lab is now scaling the technology and developing a prototype system. The researchers are also forming a startup to integrate this electrochemical approach with other recycling steps—such as black mass production—to support a circular battery economy.