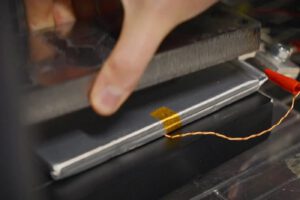

Digatron Systems provides machinery and automated production lines for the full lithium-ion battery manufacturing lifecycle, including electrode processing (mixing, coating, drying, calendaring, slitting), cell assembly (cutting, stacking, winding, welding, pouch forming, can grooving, filling, sealing), formation and aging (soaking, degassing, conditioning), cell finishing and testing (OCV, IR testing, grading, sorting), module and pack assembly (sorting, stacking, wiring, BMS integration, quality control), and advanced electrochemical, thermal, aging, and regenerative testing for pouch, cylindrical, and prismatic cells.

The product portfolio includes modular automated test systems, integrated production lines, and high-dynamic test equipment designed for laboratory-scale development, pilot assembly, and large-scale mass manufacturing of lithium-ion cells.

Supplied modular automated test systems for emerging battery chemistries, participated in Germany’s EXINOS² project on flexible cell stacking and scalable production, delivered turn-key and high-dynamic test systems to major battery producers, automakers, and research laboratories, and collaborated with Safion GmbH on advanced battery testing and analytics.

Digatron Systems is privately owned and operated by its founders and management as part of Digatron Group, with organic growth supported by its global manufacturing presence and partnerships; there are no external investors.