Group14 Technologies has reported that its SCC55® silicon battery material is enabling manufacturers to consistently achieve more than 1,500 charge cycles—and, in some cases, exceed 3,000 cycles—across a variety of applications. Data collected from over 20 customers worldwide indicates that SCC55® raises the performance bar not only for silicon-based cells but for rechargeable batteries in general.

“The data is clear: silicon batteries have crossed a critical threshold, and 1,500 cycles is the new 1,000,” said Rick Luebbe, CEO and Co-Founder of Group14 Technologies. “This performance benchmark for silicon batteries presents a new era of durability combined with higher energy density and faster charging for all types of rechargeable energy storage.”

Historically, reaching 1,000 cycles has been viewed as the standard for high-performance lithium-ion batteries. However, recent tests with SCC55® have demonstrated that silicon electrodes can maintain their key advantages while extending cycle life well beyond this benchmark. The increased cycle life is expected to reduce the total cost of ownership in sectors where battery longevity is crucial, including electric vehicles (EVs), electric vertical takeoff and landing aircraft (eVTOLs), and energy storage systems (ESS) for AI data centers.

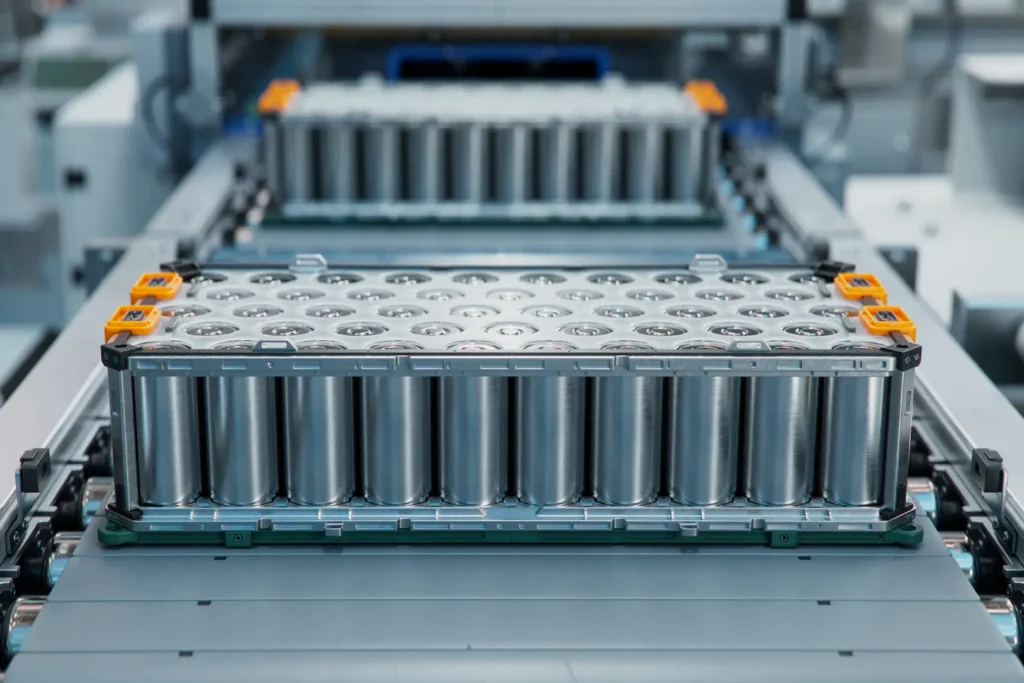

SCC55® is compatible with several cathode chemistries—such as lithium iron phosphate (LFP), lithium manganese iron phosphate (LMFP), and high-nickel formulations—allowing it to integrate into a broad range of cell designs. Group14 notes that this material is already incorporated into products that have shipped in the millions, spanning EV platforms, AI-enabled devices, eVTOL prototypes, and grid-scale storage installations.

By overcoming the cycle-life limitations traditionally associated with silicon anodes, SCC55® is positioned to set a new industry standard for rechargeable batteries. Continued customer testing and deployment across diverse applications are expected to further validate its performance advantages.