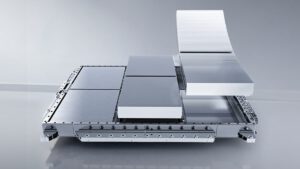

International Battery Company (IBC) has entered a collaboration with Sakuu to implement the Kavian 2000 platform for dry-process electrode manufacturing. The agreement covers production of IBC’s Prabal 6000 prismatic solid-state batteries and Prabal 4000 prismatic supercapacitors, targeting two- and three-wheeler mobility applications and AI-focused data centers.

The Kavian platform is the first commercial-scale solution that dry-prints electrodes, eliminating toxic solvents and water while enabling rapid design iterations. Compared to conventional wet-coating methods, it delivers up to a 60% smaller factory footprint, 56% lower utility costs, 55% fewer CO₂ emissions and 20% reduced capital equipment expenses, all without sacrificing performance or quality.

After nearly a year of joint development on the Prabal 1000 prismatic cell line, IBC founder and CEO Dr. Priyadarshi Panda said Sakuu’s technology addresses key manufacturing bottlenecks and will help bring advanced cell designs to new mobility and storage customers. IBC is preparing to expand its gigafactory in Bengaluru, India, through a joint venture with Mahanagar Gas Limited, in order to meet rising demand for customized battery solutions.

IBC specializes in prismatic lithium-ion cells and has deployed its Prabal 1000 series in more than 1,000 vehicles across challenging Indian environments, covering over 200,000 miles. The company operates a 35,000-square-foot development center in South Korea with 50 MWh capacity and is finalizing its first gigafactory for mobility, industrial, telecom and data center energy storage packs.

“We’re delighted to have IBC as a deep strategic collaborator,” said Robert Bagheri, founder, CEO and executive chairman of Sakuu. “Technology-forward companies like IBC recognize the need for cutting-edge manufacturing equipment and processes to build supercapacitors and batteries for the AI era. After decades of only incremental change to the battery manufacturing process, Sakuu innovations enable OEMs and cell producers like IBC and its partners to scale up production to support the growth, sustainability and efficiency demands of the future.”

Source: Sakuu News