Sodium-ion batteries have emerged as a sustainable alternative to lithium-ion cells, but they face a significant challenge: substantial capacity loss during the first charging cycle due to unwanted chemical reactions at the anode–electrolyte interface. Researchers at the Federal Institute for Materials Research and Testing (BAM) have developed an innovative core-shell anode design that substantially reduces these irreversible losses while boosting storage capacity.

In conventional sodium-ion cells, hard carbon anodes are used because sodium ions cannot intercalate into graphite. During initial charging, electrolyte molecules decompose at the porous carbon surface, penetrating its pores and occupying sites intended for sodium storage. This decomposition halts only after a protective film has formed, but the resulting layer sequesters sodium ions and reduces the battery’s available capacity.

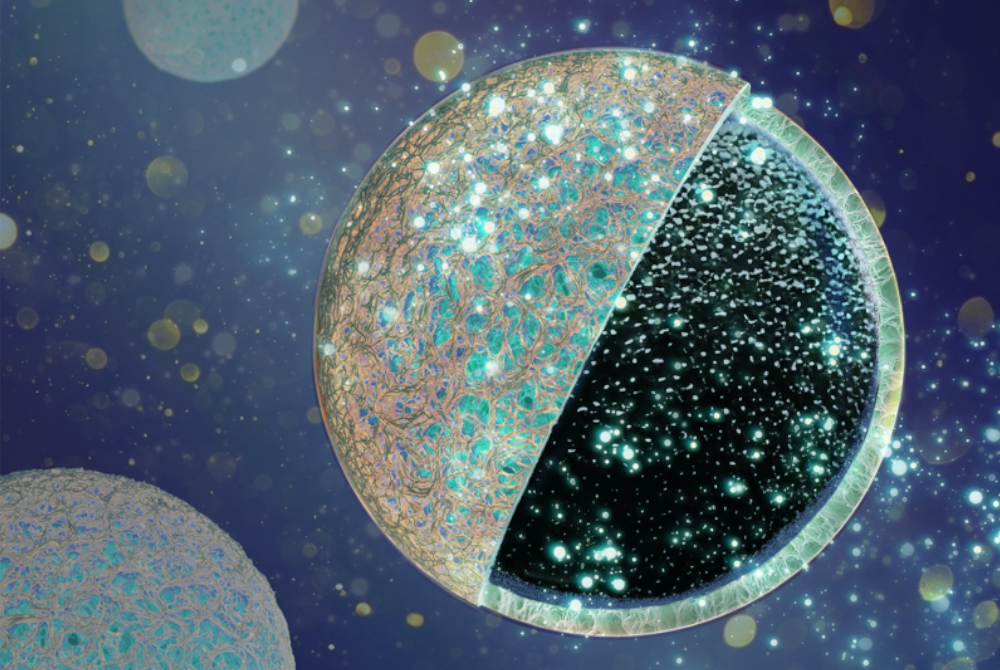

To overcome this drawback, the BAM team applied a very thin, selectively permeable coating onto a sponge-like hard carbon core. This shell permits sodium ions to pass through while blocking larger electrolyte molecules, preventing them from entering and decomposing within the carbon pores. As a result, the newly designed anode preserves its full storage capacity and supports numerous charge-discharge cycles without suffering the severe initial efficiency loss seen in uncoated materials.

Based on activated carbon, the coated anode material is both cost-effective and environmentally friendly. In laboratory tests, the core-shell electrodes achieved an initial efficiency of 82 percent, compared with only 18 percent for uncoated hard carbon. The researchers expect further improvements by refining the separate materials used for storage and protective functions. Unlike recent advances that have focused predominantly on cathode innovations, this approach explores the largely untapped potential of tailored anode materials.

The new anode will undergo additional development at the Berlin Battery Lab, a collaboration among BAM, Helmholtz Zentrum Berlin, and Humboldt-Universität zu Berlin. Funded by the German Federal Ministry of Research, Technology, and Space through the DialySorb and NMR-Batt projects, the initiative aims to accelerate the transfer of sustainable battery technologies into commercial applications.

Source: BAM Press Release