ProLogium Technology has announced that its cumulative shipments of next-generation lithium ceramic batteries have exceeded 2.4 million units since production began in 2013. A significant contributor to this milestone is the ramp-up at the company’s first gigascale facility in Taoyuan, Taiwan, which delivered more than 500,000 units within 18 months of beginning operations. ProLogium’s batteries are now deployed across electric mobility platforms, wearable devices, automotive electronics, and industrial systems, underlining the technology’s commercial maturity and consistent supply capability.

Founded in 2006, ProLogium focuses on safe, high-performance, scalable, and sustainable battery solutions. It is the only company to mass-produce all-inorganic solid-state electrolyte batteries through automated manufacturing systems. Following environmental impact and building permit approvals in late 2024 for its planned gigafactory in Dunkirk, France, ProLogium is preparing to break ground in 2026 with mass production slated for 2028. This expansion aims to strengthen the global battery supply chain and support growing market demand.

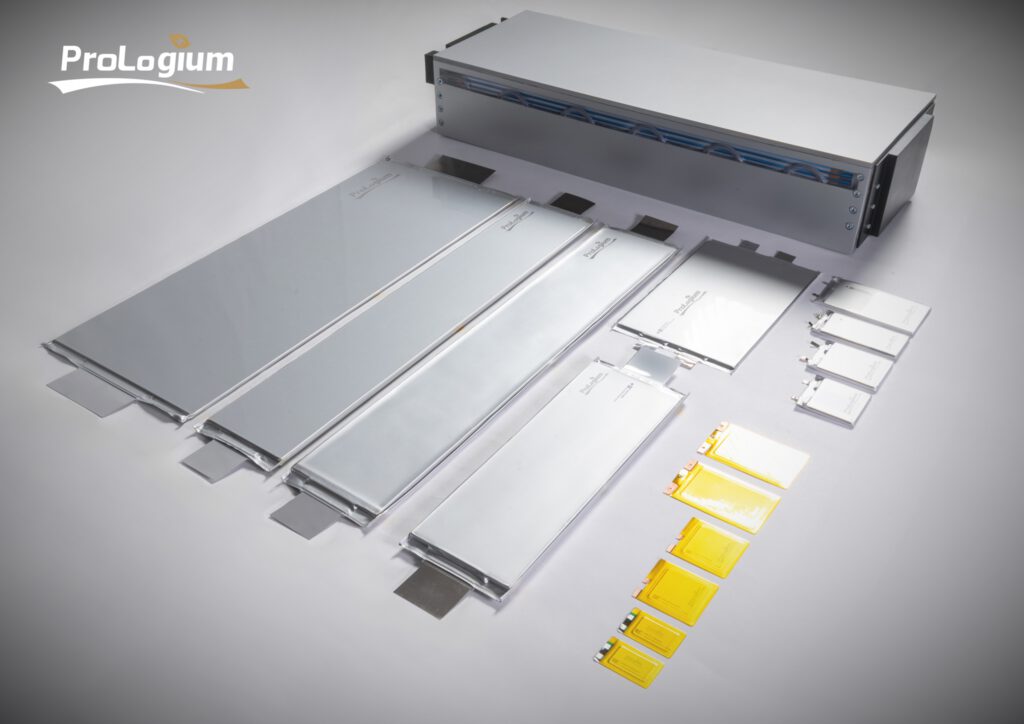

ProLogium’s fourth-generation battery architecture integrates an all-ceramic separator, an all-inorganic electrolyte, and an all-silicon anode. By employing inorganic electrolyte fluidization technology, the design combines the benefits of solid-state and liquid electrolytes, mitigating traditional trade-offs in safety, energy density, thermal stability, fast-charging capability, efficiency, and low-temperature performance. At the same time, it addresses key cost challenges associated with solid-state materials and manufacturing. The architecture also resolves interface issues between solid electrolytes and active materials, enabling scalable, cost-effective production and paving the way for broad adoption of next-generation energy storage solutions.

“Next-generation batteries are not only the cornerstone of the energy transition but also a critical engine driving electrification and smart device innovation,” said Vincent Yang, Founder and CEO of ProLogium.

“We are pleased that our technology has been adopted and validated by leading strategic partners around the world and introduced into a wide range of applications. Beyond business expansion, we look forward to collaborating with industry, government, academia, and research institutions to form strategic alliances that can accelerate energy transition and contribute to global sustainable development.”

As of mid-2025, 21% of the total shipments originated from the Taoyuan gigalevel factory, underscoring ProLogium’s growing production capacity. The company holds over 900 patents and has supplied more than 12,000 battery samples to automotive OEMs and other strategic partners worldwide.

Source: ProLogium website