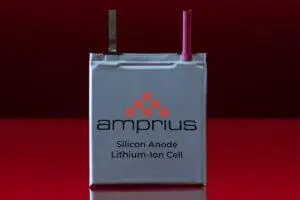

Agratas designs and produces high-performance, sustainable battery solutions for automotive and commercial energy storage applications. Their technology portfolio includes advanced cell chemistries, extended lifespan, rapid charging capabilities, and environmentally sustainable manufacturing processes. Production facilities operate on 100% clean power, integrating renewable energy and circular economy principles with material recycling and recovery. R&D Innovation Hubs in India and the UK collaborate with universities to improve cell chemistry and manufacturing processes, with production starting in 2026 at facilities in the UK (40 GWh) and India (20 GWh).

Agratas is on track to deliver advanced, high-density, modular, and smart battery systems that will support both electric vehicles and large-scale energy storage, with industrial production set to begin in India and the United Kingdom by 2026. Agratas, with the support of Tata Technologies, creates battery packs tailored to specific applications by integrating cells into modules and adapting pack architectures to customer requirements, particularly for Tata Motors and JLR electric vehicles.

Agratas established a new R&D facility at Milton Park, Oxford, in late 2024, enhancing research capabilities in the UK. It has a strategic partnership with Tata Technologies to accelerate product development in mobility and energy sectors. The company is constructing a gigafactory at the Gravity Smart Campus near Bridgwater, Somerset, the largest battery manufacturing plant in Britain, with an investment over £4 billion and approximately 4,000 direct jobs.

Primary investor Tata Sons invested ₹9.5B in battery manufacturing operations. Plans for Tata Sons to sell a 20.0% stake to Singapore-based AESC Apollo Holding for about ₹37B and discussions about a future IPO to raise additional capital.